Custom Quote Request Form

Chipboard Packaging

FAQ'sSpecification Learn More Reviews |

||||||||||||||||

|

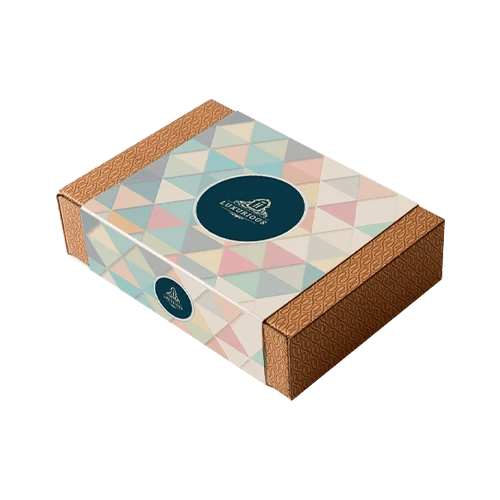

Q: What is the difference between corrugated and chipboard?A: Corrugated and chipboard are made from the same paper material, but have a different structure. Corrugated cardboard is thicker and sturdier, which means it is ideal for storing and transporting heavier items. Chipboard is thinner and smoother, with a more attractive appearance. Corrugated tends to be more expensive than chipboard, and takes up more storage space. Q: Is my artwork checked for errors and technical issues such as image resolution?A: Yes. We include a free artwork check with every order. Your artwork is checked for technical issues before printing. Any issues found are either fixed or we will contact you if further action or your input is needed. Please do note that this is only a technical check. Any spelling, grammatical, or positioning issues are not checked during this process. Q: Can you send me samples of your custom chipboard boxes?A: We can send samples of our recent print orders. Please submit a sample request and our sales representative will be in touch so that appropriate chipboard box samples can be sent. Q: What file format should I use for best results?A: Any non-photographic content (including graphics and text) should be uploaded as vector-based files in order to ensure that lines are crisp and clear. Some content such as logos typically needs to be separated from the background, resized, or otherwise manipulated. Vector images offer the most flexibility for these purposes. Supported formats currently include Ai, CDR, PSD and pdf. If you have any questions with regards to file preparation, please feel free to contact your account representative. Q: What options can I add to my custom chipboard boxes?A: These are the most commonly used options when designing chipboard boxes: Spot UV Varnish: Spot UV varnish is an ultra-high gloss finish that can be applied over a matte or soft-touch laminate in order to highlight specific areas of a page. It can also look particularly effective when used to print a glossy logo over a flat colour. Foil stamping: Foil stamping is a process where a shiny foil sheet is physically stamped with heat and pressure onto the card for an enhanced decorative look. You can consult with our sales representative for more details and specific colour availability. Embossing & Debossing: Embossing or Debossing is the process of leaving a relief imprint on the card. It is applied by utilizing an engraved metal die. When such a die is pressed on the card with an appropriate level of pressure, it leaves an impression.

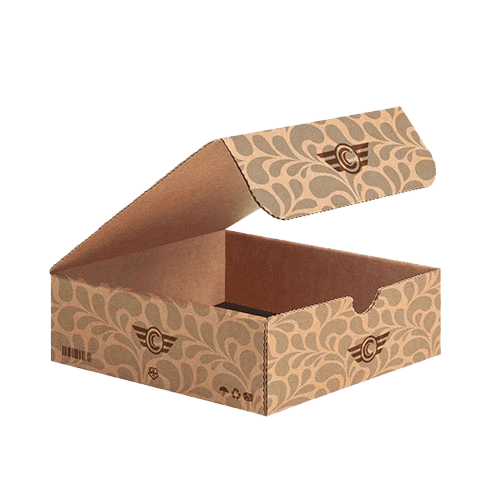

Order Custom Printed Chipboard BoxesChipboard boxes are another option for your packaging toolkit. Although we are proud of our full-colour printing technology, colourful packages are not always appropriate for every application—even if they’re eye-catching. For some products and circumstances, one- or two-colour packaging is best. A custom printed chipboard box can be an elegant and durable solution. Simple, understated colours and designs look right for certain products and boxes. What Is Chipboard Cardstock?Chipboard is similar to cardboard, but is sturdier and usually has an uncoated side. It’s thicker than regular cardboard, which makes it durable, but it’s also thin and flexible enough to be shaped. As examples, we can fold it into:

Chipboard also has the advantage of absorbing moisture to protect your products. We can supply various thicknesses of the chipboard for different situations. Printing on Custom Chipboard BoxesCompetition in today’s economy is fierce. Our experienced printing engineers and designers can help you pay extra attention to your packaging to pull ahead. To make your job easier, Printingblue.com.au offers:

We'll use newest printing technologies to apply graphics and lettering to your personalised chipboard boxes. Make the design as complex or minimalist as you'd like. Browse through our gallery of custom retail packaging styles for inspiration. Order a free sample kit to get tangible examples of the packages and boxes we could create together. |