Custom Quote Request Form

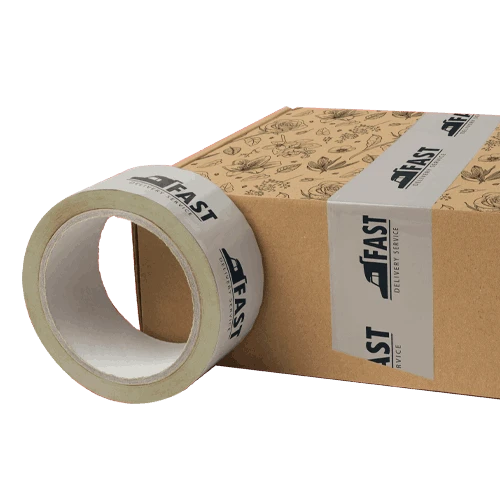

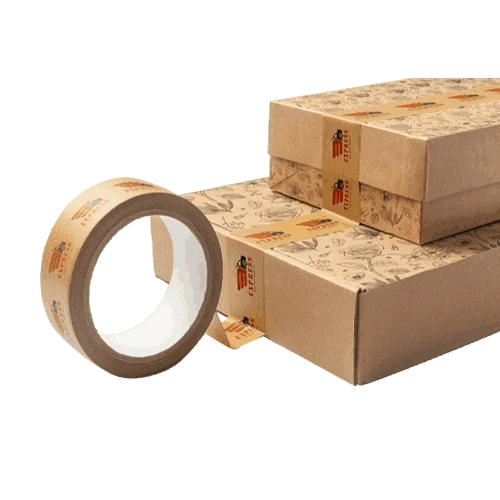

Packaging Tape Rolls

FAQ'sSpecifications Learn More Reviews |

||||||||||||||||

|

Q: Can I have continuous print on my tape rolls?A: Yes, you can have continuous print on your tapes. Please get in touch with our support team at (03) 8652-1144 for a custom quote. Q: What file formats should I send for the printing of my packaging tapes?A: Supported formats currently include Ai, EPS, PSD, and pdf. However, for highest quality results, we recommend creating the design in a CMYK file format. Q: What is a water-activated tape?A: Water-activated tape is a paper-based tape that feels dry before use and is activated by water. After a little bit of water is applied to the glued edge of the tape, the dry glue turns into a strong adhesive that adheres to cardboard and corrugated material easily. Q: Do I need special equipment to activate water-activated tape?A: While using a specialized tape dispenser is recommend, it is not compulsory. The tape can also be used with the aid of a wet sponge. When using a wet sponge, it is better to cut a portion of the tape and then apply water with the sponge. On the other hand, specialized water-activated tape dispensers have wet sponge rollers that moisten the tape as it pulled through. In addition, the perforated blades on the dispenser helps in cutting the tape evenly during application. Q: What are the advantages of using pressure-sensitive tape rolls?A: Pressure-sensitive tape rolls, commonly known as polypropylene tapes, provide a quick and easy solution to pack corrugated and cardboard packaging boxes. This type of tape is ideal for sealing both light and heavyweight boxes. Q: What are the most common types of custom printed tape rolls?A: Printed tape rolls can be manufactured using various types backing paper and adhesive types in order to ease of use. The most common types are: Water Activated Tape: Also referred to as gummed tape, this type of tap is made from a paper based backing paper and starch-based adhesive. Once moisturized with water, the starch-based adhesive is activated and can be applied easily to seal personalised cardboard boxes and recyclable corrugated mailers.The strong adhesive makes it suitable for securing paper mailers and packaging boxes commonly used for shipping. Heat Activated Tape: This type of tape is made from a thermoplastic film and the adhesive is activated only when both heat and pressure is applied during the application process. This type of tape is widely used in manufacturing apparel products, packaging textile products, and securing branded product boxes. Double Coated Tape: This is a pressure sensitive adhesive tape that is manufactured using foam, cloth, and paper material. The high temperature performance of this tape makes it ideal for use in settings where the tape may be exposed to extreme temperatures. Foam Tapes: Foam tapes are double coated tapes and are coated with acrylic or paper layer on both sides. This type of tape is widely used for mounting and sound damping purposes.

The Importance of Quality Packaging Tape in ShippingA packaging tape roll is a roll of pressure-sensitive adhesive tape used to seal packages for shipping and storage. It is typically made of a thin plastic film or recycled kraft paper material coated with a pressure-sensitive adhesive. It is available in many colours, lengths, and widths and is often used with other packaging materials such as bubble wrap, packing peanuts, and cushioning foam. Quality packaging tape is crucial in the shipping industry. A package's safe arrival at its destination depends on many factors, and one of the most important is the tape used to seal it. Here are some of the reasons why quality packaging tape is important in shipping:

In conclusion, using quality packaging tape is essential to the shipping process. It helps to ensure the safe arrival of packages, prevents tampering, maintains brand image, increases efficiency, and is cost-effective in the long run. Applying packaging tape effectively and efficiently ensures that packages are properly sealed and secure for transportation. Here are some tips for using packaging tape:

Applying packaging tape effectively and efficiently will also help to save time and effort, making the packaging process smoother and more efficient. The materials used for packaging tape can vary depending on the specific requirements of the packaging. Common materials used in packaging tape include:

The choice of material will depend on the specific requirements of the packaging, such as weight, contents, and environmental conditions. |